In recent years, the demand for Vacuum Casting plastic parts has increased in the industry and market. Vacuum Casting allows people to make the most popular consumer electronics products due to the top-notch quality and incredible detail achieved. Therefore, they are an excellent choice for ambitious projects ranging from Medical to the Aerospace cluster.

But how do we do it at ARRK North America? As experts in Product Development, we have focused for years on specializing in various industrial processes to provide our customers with the expected quality and the possibility to make tangible what they envisioned.

What are the benefits of Vacuum Casting in the prototyping and production of plastics—as well as other materials—and what is the scope of this method? Let’s keep talking about it.

Achieving All the Possibilities With Vacuum Casting

What can be achieved with the Vaccum Casting process at ARRK? Here are a few key points:

- Versatility & Complexity

We can all agree that silicone is one of the most versatile materials available. The master model is made of this material, so there is no need to cut anything when removing the part from the master model. Also, this allows us to create complex designs that are impossible with other processes—such as Tooling and Injection Molding—because the process makes it difficult.

- Finishes and colors

Our experience allows us to create different smooth and rough finishes using ABS, urethane rubber, or clear, as well as fire retardant and fire-resistant materials. It is also possible to obtain colored or transparent parts with shading over the entire surface or with various effects. Of course, we do not paint the pieces afterward; each component has the color specified by the customer, increasing the quality and providing an excellent appearance to the resulting piece.

- Flexibility

Vacuum Casting is a designer-friendly process since it allows constant changes to the design without high additional costs due to machinery changes. On the contrary, if the first batch, which usually produces 10 to 15 parts, requires changes, only the master model design is modified, and the next batch will have those changes implemented. This flexibility also makes it useful for both Prototyping and Low-Volume Production .

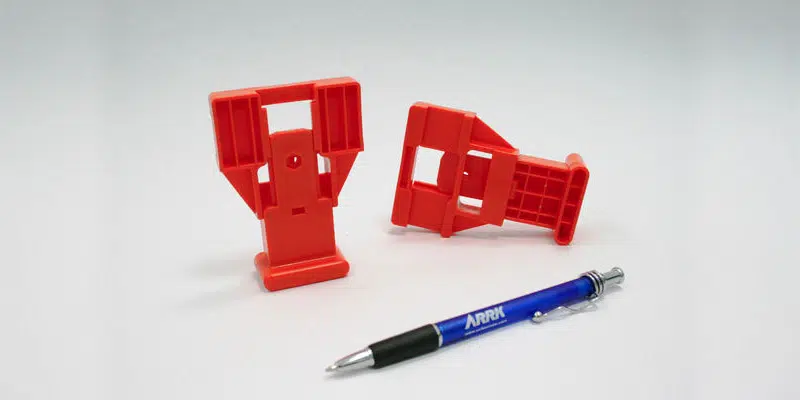

At ARRK North America, we have become casting masters, providing the market with top-quality Vacuum Casting plastic parts and products so companies can improve operations, increase sales, and reach their full potential.

ARRK’s processes allow us to obtain finished goods with as much detail as our customers require, delivering what they envisioned in the first place. Contact us for more information, or click here to get a quote! We will be happy to work with you.