Mastering Innovation: Get the Best Prototyping Solutions

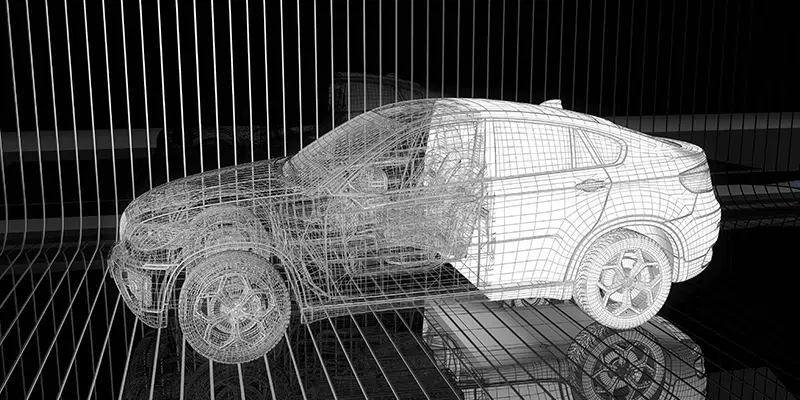

ARRK’s prototyping solutions help companies enter the fast-paced realm of product development, by offering manufacturing methods that optimize production.

ARRK’s prototyping solutions help companies enter the fast-paced realm of product development, by offering manufacturing methods that optimize production.

Working with Vacuum Casting silicone mold has given companies important advantages regarding their components and increased the quality of their production.

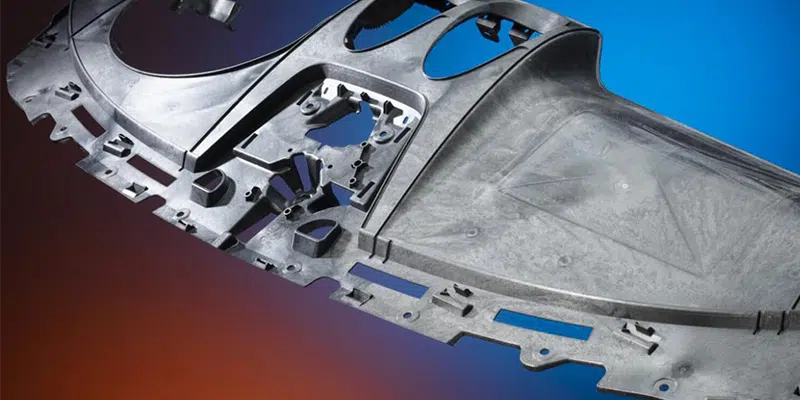

At ARRK North America, we’ve repeatedly proven that prototype vacuum forming is an ideal way to get complex shapes and outstanding results for customers.

Vacuum Casting is a technique used in many industries due to its amazing flexibility. What materials can be vacuum cast? Learn more about their properties.

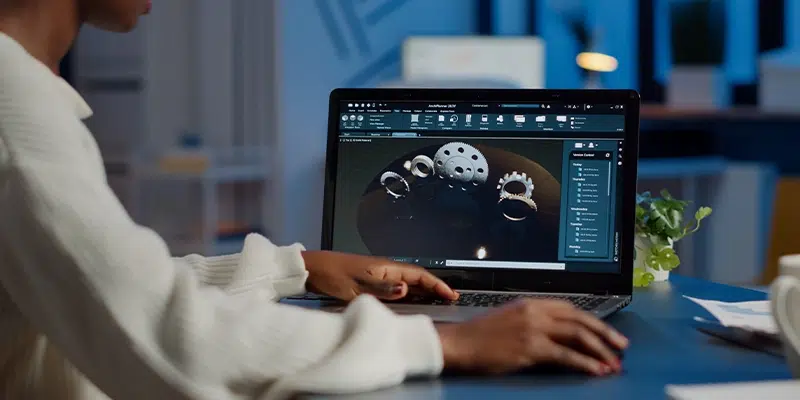

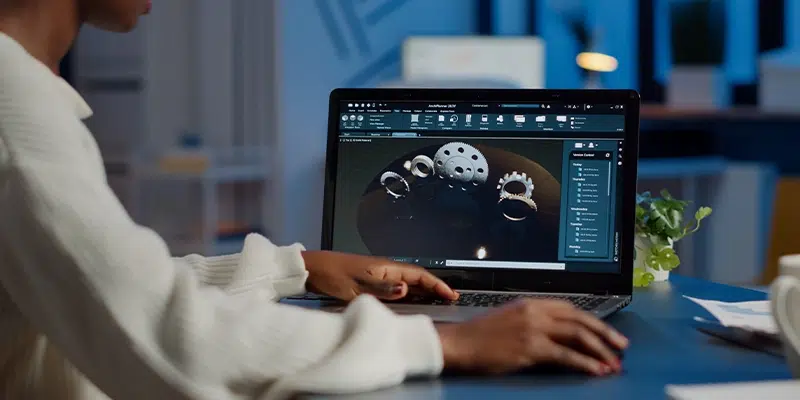

At ARRK North America, the Design Model process for Prototyping is one of our top services because of what we can achieve as design and engineering experts.

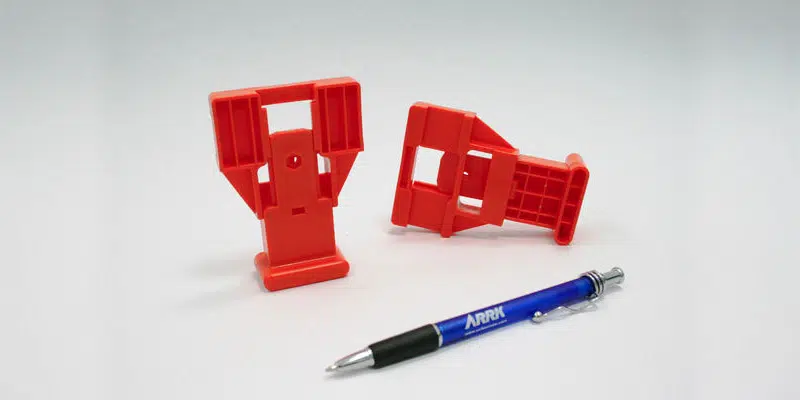

Companies need precision and flexibility for their production, and Vacuum Casting plastic parts are a versatile choice to deliver exactly what they need.

Our Vacuum Casting prototyping projects have added innovation and given powerful tools to companies that require small batches and high-quality results.

High-tech vertical farming manufacturing is necessary to improve productivity and agricultural processes, but also to supply the population’s food demand.

Fabricate custom silicone rubber prototypes efficiently with ARRK and learn more about the properties of these materials for your manufacturing processes.

By knowing the benefits that custom silicone prototypes can provide, your company can give your products a better result to your customers.

© 2024 ARRK North America, Inc. All rights reserved. Here are our Terms & Conditions, Privacy Policy, and Code of Conduct.