Look around and check any product you have near you. Have you ever wondered what process took place for that product to be in your hands? Most things surrounding you were an idea before becoming an object you can touch. In fact, some items were just rough drafts of the products they would become in the future.

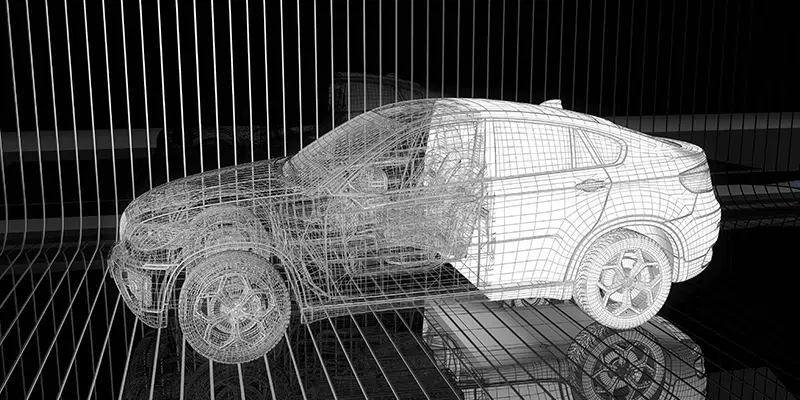

That’s what we do at ARRK North America: we make ideas happen. We work on Product Design and Development, which means we develop parts for evaluation or Low-volume Production. To do this, the Design Model process for Prototyping is crucial. Let us tell you more about it.

Design Model: Trial and Testing

Design Model is a manufacturing process in which companies request a preview of their design for evaluation and market testing. Here, they make the necessary adjustments and get the final prototype to meet functionality requirements as if it were the final product.

At ARRK, we perform End-to-end Services. Our Design Model service is available for those companies that wish to obtain finished goods with as much detail and care as necessary. To achieve this, we comply with a flow that allows us to achieve the desired quality and maintain the best communication with our clients.

Concept Design: In the first stage of Product Development, we talk to the customer about the project, specifications, product’s function, and all the necessary information. In addition, we work with the given design, and then our designers and engineers provide insights and feedback on adjustments and challenges to be solved.

Also, we select the necessary materials to give the piece the appearance and finishes needed so that the product feels, looks and functions in the best way.

Prototyping: Here, we carry out 3D Printing, obtaining a physical model of everything discussed in the conceptualization stage. For this, it is necessary to select the most appropriate method for the project, which varies between Stereolithography, Selective Laser Sintering, Polyjet 3D Printing, FDM 3D Printing, and Direct Metal Laser Sintering.

Also, our Vacuum Casting prototyping projects , Urethane Casting, CNC Prototyping, and Microwave Molding services are ideal for attention to detail and speed. Each technique provides different results, but all are excellent for prototyping projects.

At ARRK, we also specialize in the different Design Model areas, such as the following:

- Mechanical Design Model

- Lighting Desing Model

- Soft Goods Design Model

With our top-notch Design Model process for Prototyping, your company can accomplish marvelous results for design evaluation and prelaunch publicity. By working closely with our experienced staff, it will be possible to have in your hands the prototype that will look just like the final product you envisioned in the first place.

If you’d like to work with Product Development global leaders, we will be happy to help you. Contact us to get a quote and start your Prototyping project!