FUSED DEPOSITION MODELING

Home » FDM 3D Printing

FDM 3D PRINTING GIVES YOU MANY OPTIONS OVER BUILD SIZE AND LAYER HEIGHT

HIGH PERFORMANCE

Withstands harsh environments and rigorous testing

VERSATILITY

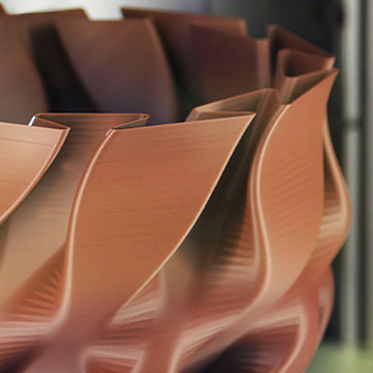

Produce geometries only attainable with 3D printing

SHORT LEAD TIME

Prototypes delivered in time to meet product release goals

FUSED DEPOSITION MODELING

THERMOPLASTIC MATERIALS PROVIDE A VARIETY OF BENEFITS

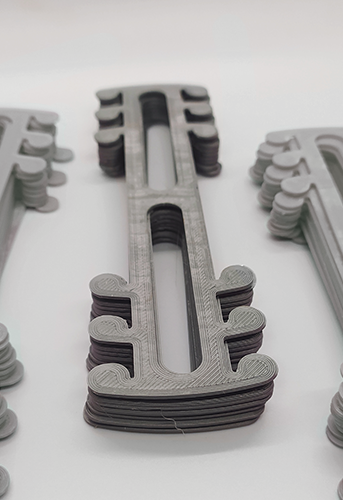

- FDM parts are built in strong, engineering grade materials ABS, Polycarbonate, ULTEM™ 9085, and other resins. They have exceptional mechanical properties so they can be drilled, tapped, and threaded. Plus, outstanding thermal and chemical resistance provides stability so they will not shrink or warp over time.

FDM’S GREAT ADVANTAGE IS HIGH STRENGTH ROBUST PARTS

- Because prototypes made using this technology are actual production grade thermoplastics, they offer a much higher level of durability making them ideal for end use parts. Desired appearance can also be achieved through this method, as prototypes are available in many colors making them suitable for color coding production fixtures.

EXPERIENCE

One-Stop Solution

Concept Design

Rough

Sketch

Define Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

One-Stop Solution

Concept Design

Rough

Sketch

Define

Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre/ Mass Production

DFM

Tooling

Production

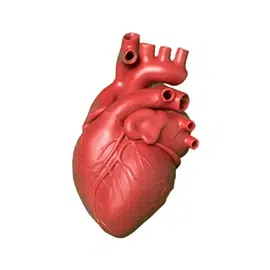

PRODUCT IMAGES BY INDUSTRY

- All

- Automotive

- Consumer products

- Defense

- Medical

- Robotics

BLOGS & NEWS

What Methods Can Produce Rapid Prototype Machined Parts?

Rapid prototype machined parts can be produced using different kinds of manufacturing methods. We are experts in rapid prototyping, learn more about it.

ARRK’s Comprehensive Manufacturing: Soft Goods Prototyping

Our engineers know that soft goods prototyping requires meticulous processes and methods, same as using high-quality materials to achieve excellent results.

A Powerful Fusion: CNC Machining Rapid Prototyping Method

At ARRK, we are constantly looking for ways to enhance our manufacturing processes and product development services, like CNC machining rapid prototyping.

Plastic Molding and Manufacturing for Diverse Industries

Plastic molding and manufacturing have a long trajectory in modern processes for diverse industries. Injection molding is one of ARRK’s preferred solutions.

TESTIMONIALS