DLP 3D PRINTING SERVICES; ELEVATING YOUR CONCEPTS LAYER BY LAYER.

Home » DLP 3D Printing

From Aerospace to Automotive, Agriculture to Medical, ARRK’s DLP 3D Printing service brings new possibilities to your project.

ARRK & DLP 3D Printing

What is DLP 3D Printing?

Unleashing Potential: Our Specialized Materials for Every Project

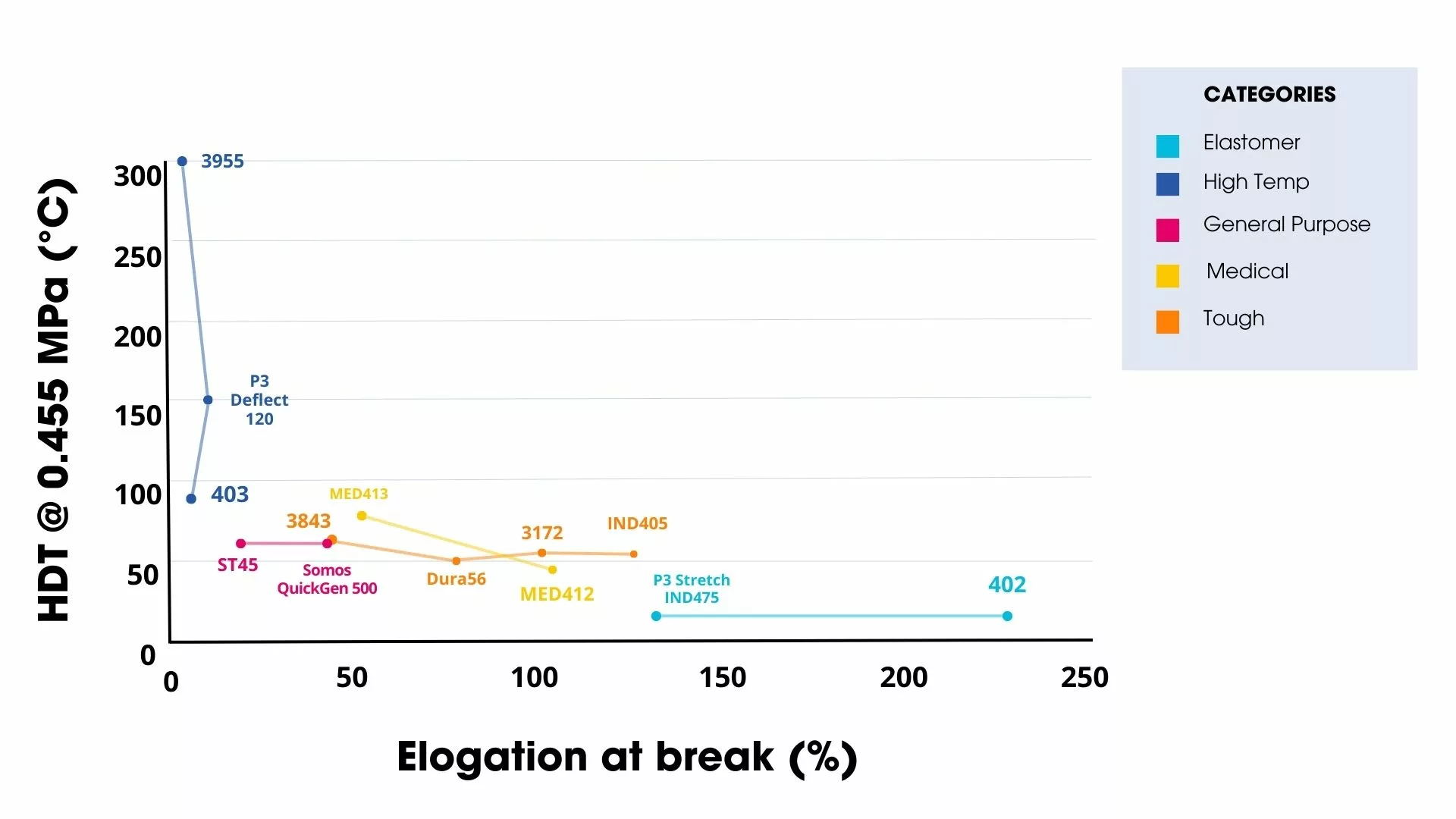

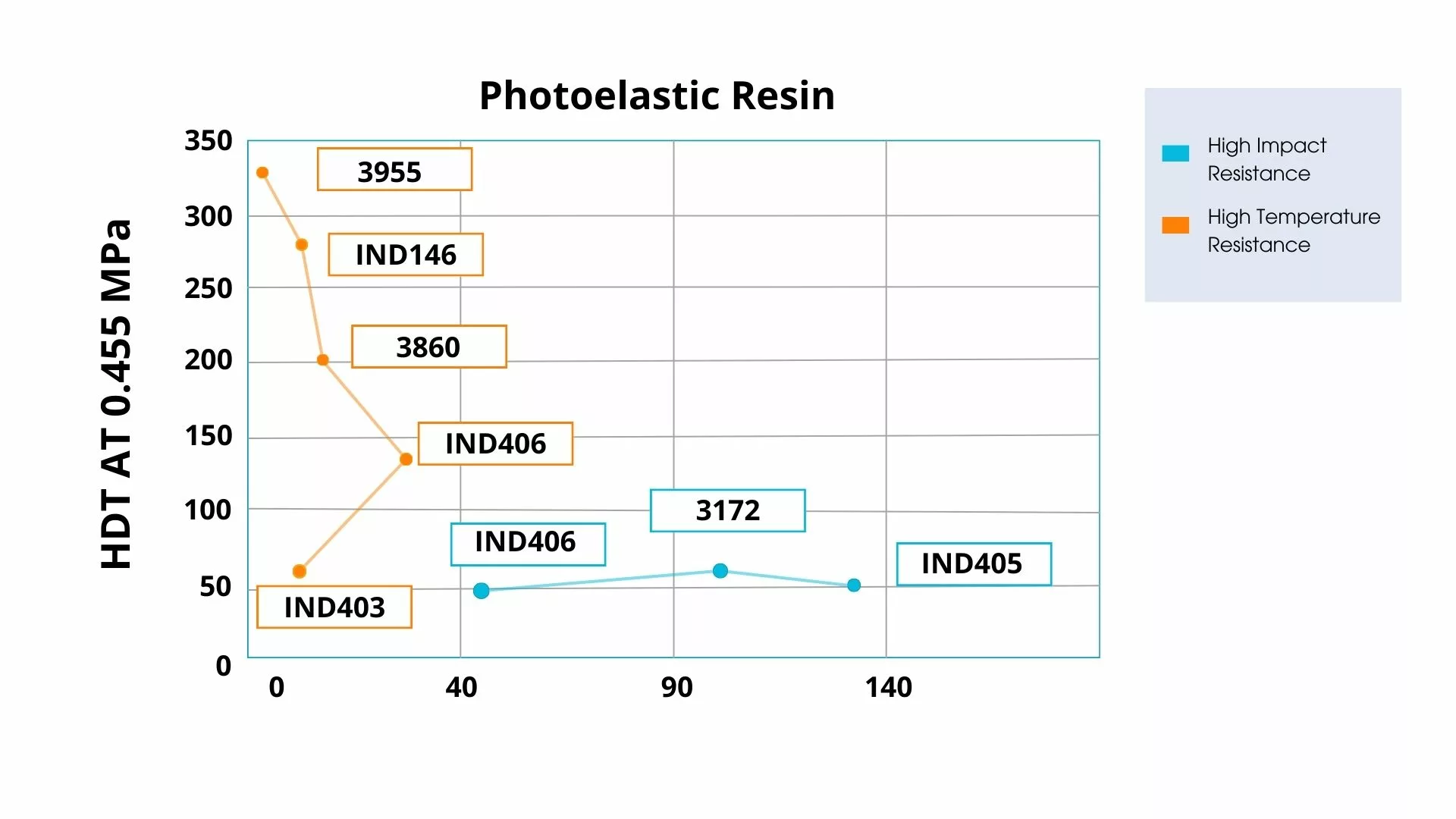

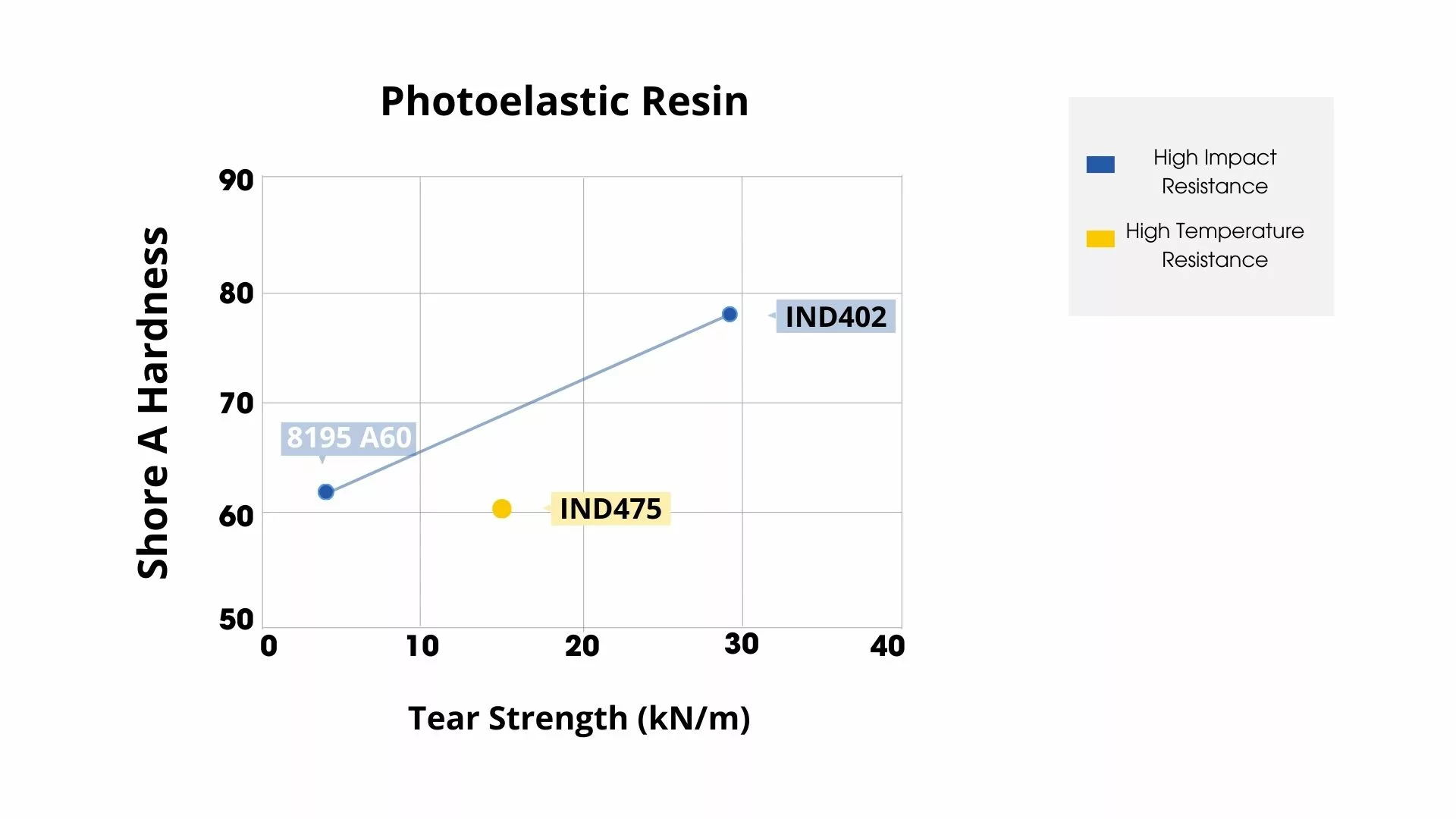

Our specialty DLP materials not only meet exceptional quality standards, but also provide strength and durability for optimal performance. Our teams will work closely with you to ensure the material section meets your project requirements. We don’t just offer materials, we provide reliable and durable solutions to exceed your every expectation.

| Properties (Type) | ST 6100L (GF-Nylon) | TI 3100L (PP) | RG 3101 (ABS) | RG 7100L (ABS) | TI 5400L (PP) | RG 2000L (ABS) |

|---|---|---|---|---|---|---|

| Tensile Strength (MPa) | 89 | 35 | 52 | 51 | 43 | 53 |

| Elongation (%) | 6 | 120 | 32 | 48 | 405 | 60 |

| Notched Izod (J/m) | 22 | 40 | 45 | 80 | 30 | 44 |

| HDT @.455 MPa (⁰C) | 120 | 47 | 79 | 66 | 56 | 78 |

Temperature and Resistance Innovation

EXPERIENCE

Understanding ARRK's DLP printing service

DIGITAL PROJECTION

RESIN SOLIDIFICATION

LAYER-BY-LAYER BUILD

WASH & POST-PROCESS

DIGITAL PROJECTION

RESIN SOLIDIFICATION

LAYER-BY-LAYER BUILD

WASH & POST-PROCESS

Precision and Detail: Unlocking ARRK's DLP 3D Printing Advantages

Versatile Materials

High precision & detail

Faster lead time

INDUSTRIES

Aerospace

Robotics

Medical

Industrial

Consumer Products

Transportation

Drones