SELECTIVE LASER SINTERING

Home » Selective Laser Sintering

USING SLS ADDITIVE MANUFACTURING TO DELIVER PROTOTYPES WITH HIGH STANDARDS

TESTING ANALYSIS

Form, fit and function testing in rigorous environments

DESIGN FLEXIBILITY

With no support structure requirement complex geometries can be achieved

RAPID DELIVERY

We provide quality functional parts in fast time frames

SELECTIVE LASER SINTERING

A VARIETY OF MATERIALS AVAILABLE

- Clients can choose from a wide range of materials, each offering its unique characteristics. From Nylon 12 PA to glass filled Nylon 12 GF, Selective Laser Sintering is particularly suited for functional testing, and EX material combines adequate durability with exceptional flexibility.

ADVANTAGES OF SLS 3D PRINTING TECHNOLOGY

- The flexibility of the Selective Laser Sintering additive manufacturing process is significant and a key competitive advantage offering customers the opportunity to respond quickly to market needs when bringing products to market.

DELIVERING OUTSTANDING PRODUCTS

- At ARRK, we believe in an integrated approach to product development backed at every stage by exceptional engineering skill, cutting edge technology, and expert guidance. ARRK’s SLS service delivers tough, durable parts in just a few days.

EXPERIENCE

One-Stop Solution

Concept Design

Rough

Sketch

Define Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

One-Stop Solution

Concept Design

Rough

Sketch

Define

Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre/ Mass Production

DFM

Tooling

Production

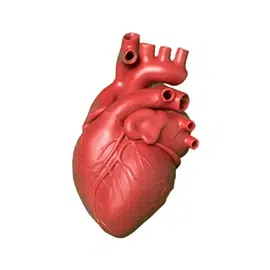

PRODUCT IMAGES BY INDUSTRY

- All

- Automotive

- Consumer products

- Defense

- Medical

- Robotics

BLOGS & NEWS

What Methods Can Produce Rapid Prototype Machined Parts?

Rapid prototype machined parts can be produced using different kinds of manufacturing methods. We are experts in rapid prototyping, learn more about it.

ARRK’s Comprehensive Manufacturing: Soft Goods Prototyping

Our engineers know that soft goods prototyping requires meticulous processes and methods, same as using high-quality materials to achieve excellent results.

A Powerful Fusion: CNC Machining Rapid Prototyping Method

At ARRK, we are constantly looking for ways to enhance our manufacturing processes and product development services, like CNC machining rapid prototyping.

Plastic Molding and Manufacturing for Diverse Industries

Plastic molding and manufacturing have a long trajectory in modern processes for diverse industries. Injection molding is one of ARRK’s preferred solutions.

TESTIMONIALS

INDUSTRIES

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation