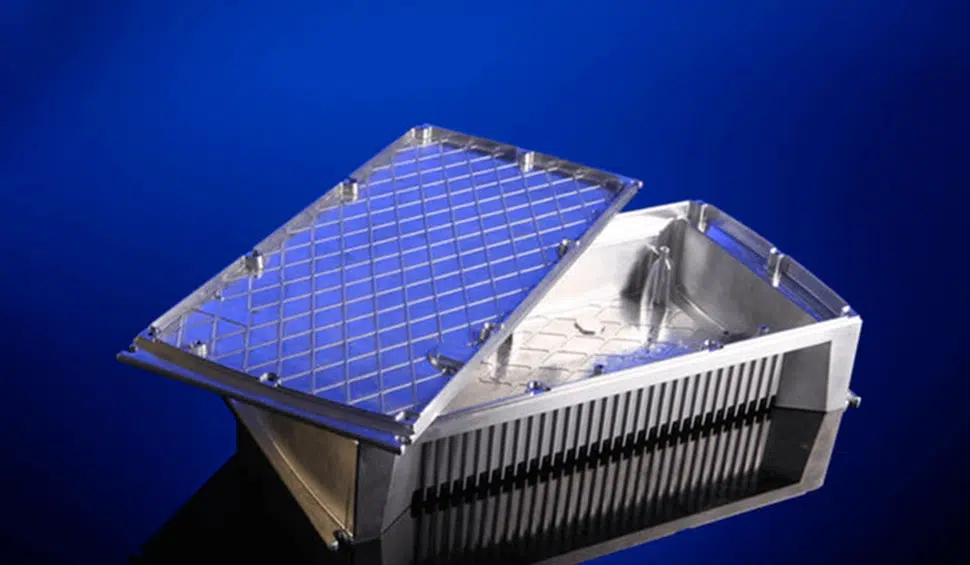

CNC MACHINING FOR PROTOTYPING

ARRK NORTH AMERICA INC WILL TAKE YOUR COMPLEX CNC RAPID PROTOTYPING PROJECTS TO NEW LEVELS OF EXCELLENCE

MORE CHOICES

Wide range of resins, size, finishing options

HIGH QUALITY

Accurate and high quality cast copies with an immaculate finish

SPEED TO MARKET

Quick turnaround for a reduced time to market

ARRK NORTH AMERICA INC’S CNC MACHINING PROCESS

SELECTION

PREPARATION

MILLING

FINISHING

SELECTION

PREPARATION

MILLING

FINISHING

WHAT IS CNC MACHINING

COMMUNICATION

- Tolerances

- High Precision

- Production Volume

- First Article in compliance to several standards

- Materia and process traceability

- Certificate of Conformance

- Certificate of Materials

- Design Geometry

BENEFITS OF CNC MACHINING

TIME EFFICIENCY

ACCURATE MEASUREMENTS

SHORTER PREPARATION

TIME EFFICIENCY

ACCURATE MEASUREMENTS

SHORTER PREPARATION

THE RESULTS YOU WANT RIGHT FROM THE START

- Extraordinary design

- Top-notch industry materials

- Experienced handling of the machining center and parts created

The most important thing that all manufacturers should have is precision & experience for execution, and we can provide it.

To learn more about our innovative technologies and masterful expertise in CNC machining for low-volume production, contact one of ARRK North America Inc’s representatives for a comprehensive guide to the development stages.

EXPERIENCE

One-Stop Solution

Concept Design

Rough

Sketch

Define Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

One-Stop Solution

Concept Design

Rough

Sketch

Define

Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre/ Mass Production

DFM

Tooling

Production

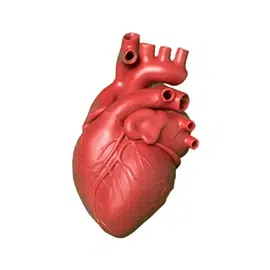

PRODUCT IMAGES BY INDUSTRY

- All

- Automotive

- Consumer products

- Defense

- Medical

- Robotics

BLOGS & NEWS

What Methods Can Produce Rapid Prototype Machined Parts?

Rapid prototype machined parts can be produced using different kinds of manufacturing methods. We are experts in rapid prototyping, learn more about it.

ARRK’s Comprehensive Manufacturing: Soft Goods Prototyping

Our engineers know that soft goods prototyping requires meticulous processes and methods, same as using high-quality materials to achieve excellent results.

A Powerful Fusion: CNC Machining Rapid Prototyping Method

At ARRK, we are constantly looking for ways to enhance our manufacturing processes and product development services, like CNC machining rapid prototyping.

Plastic Molding and Manufacturing for Diverse Industries

Plastic molding and manufacturing have a long trajectory in modern processes for diverse industries. Injection molding is one of ARRK’s preferred solutions.

TESTIMONIALS

INDUSTRIES

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation