Plastic molding and manufacturing stand as a cornerstone for diverse industries. Nowadays, there are several types of plastic molding. At ARRK North America, we take pride in our commitment to employing high-caliber processes that yield superior products. Notably, our proficiency and preference lie in the domain of injection molding. Keep reading to know how you can take advantage of this manufacturing approach.

Precision is the hallmark of any successful product development endeavor, and plastic molding is no exception. Our engineering expertise ensures that every molding project is executed with meticulous attention to detail. From the initial design phase to the final production, our team employs cutting-edge technologies to optimize the manufacturing process. This precision engineering not only enhances the quality of the end product but also significantly reduces production lead times.

Prototyping remains a critical phase in the product development lifecycle, allowing for the validation of designs and the identification of potential improvements. In the realm of plastic molding, our prototyping services play a pivotal role in refining concepts before full-scale production. With rapid prototyping techniques, such as custom 3D Printing and Rapid Prototyping Stereolithography, we empower our clients to iterate quickly, accelerating the innovation cycle and reducing time-to-market.

How does Injection Molding work?

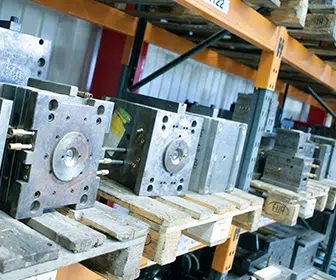

Injection molding is a widely used manufacturing process for producing parts by injecting molten material, typically plastic, into a mold. This mold, often made of metal, is designed to shape the material into the desired form as it cools and solidifies. Injection molding is a versatile and highly efficient method, particularly suitable for mass production of complex and intricate components across various industries. With us, our clients can also benefit from Low-volume injection Molding.

Advantages of Injection Molding

- High Precision and Complexity: Injection molding allows for the production of highly detailed and intricate parts with consistent quality. The mold design ensures precise replication of the desired shape, even for complex geometries.

- Cost-Effective for Mass Production: Although the initial tooling and setup costs can be relatively high, the per-unit cost decreases significantly in large-scale production runs. This cost-effectiveness makes injection molding economically viable for producing a large quantity of parts.

- Wide Material Compatibility: Injection molding supports a broad range of materials, including various thermoplastics and thermosetting polymers. This flexibility allows manufacturers to choose materials with specific properties, such as strength, flexibility, or heat resistance.

- Consistent Quality: The automated nature of injection molding ensures consistent part quality. The process minimizes the risk of human error, leading to uniformity in the molded products.

- Surface Finish Options: The process can yield parts with a smooth and polished surface finish, eliminating the need for additional finishing steps in many cases. This can be particularly advantageous for parts where aesthetics are important. At ARRK, we offer a wide variety of finishing options to achieve the expected results.

Plastic molding and manufacturing have played a transformative and indispensable role in product development throughout the years, evolving from a novelty material to a cornerstone of modern industry. The history of plastic in manufacturing can be delineated into key phases, each marked by technological advancements, changing perceptions, and an expanding array of applications.

There is a diverse range of plastics used in manufacturing, each with its unique properties and applications. These plastics can be categorized into different families based on their chemical structure and properties. To mention a few: Polypropylene, Acrylonitrile Butadiene Styrene, Polyvinylidene Fluoride, Polyimide, and many others.

These are just a few examples, and the diversity of plastics allows for a wide range of applications across various industries. The selection of a specific type of plastic depends on factors such as the intended use, required properties, and environmental considerations. Advances in polymer science continue to introduce new materials with enhanced properties, expanding the possibilities for manufacturing applications.

Plastic molding and manufacturing are undergoing a transformative journey, driven by innovation and technological advancements. As a global provider of product development support services, our commitment to excellence is evident in our prowess in precision engineering and manufacturing. By embracing these advancements, we empower clients across diverse industries to navigate the complexities of modern product development and bring their visions to life with efficiency and precision. As the landscape continues to evolve, our dedication to staying ahead of the curve ensures that we remain a trusted partner in the journey of turning ideas into reality.

Embrace innovation by working hand in hand with us. We can help you develop your projects. Contact our customer service department to get additional information about our services and get a quote. We will be happy to assist you.