One cutting-edge method that has gained traction in recent years is the Microwave Molding Process. In our experience, this revolutionary technique is transforming the manufacturing landscape, particularly in engineering, prototyping, and low-volume production. As a global leader in product development support services, our company stands at the forefront of embracing and implementing this game-changing technology across diverse industries.

If you are wondering what is the microwave molding process, we explain it here. It’s an advanced manufacturing process that leverages the power of microwaves to heat and cure composite materials rapidly. Unlike traditional methods, which often involve time-consuming and energy-intensive processes, microwave molding offers a faster and more efficient alternative. The core principle revolves around utilizing microwave energy to uniformly heat the material, facilitating a controlled and accelerated curing process.

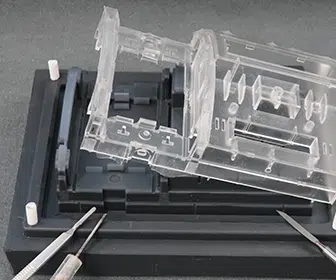

It may come as a revelation that the technology employed in our system bears a resemblance to that utilized in commonplace household microwave appliances. Nevertheless, it is imperative to note that our microwaves are meticulously engineered with a distinct purpose—to facilitate the precision molding and controlled melting of the micro-pelletizing resins designated for each component.

Key Advantages of Microwave Molding

- Speed and Efficiency: Microwave molding drastically reduces production cycles, enabling quicker turnaround times for prototypes and low-volume production runs. This acceleration in the manufacturing timeline translates to cost savings and a competitive edge in time-sensitive industries.

- Precision and Consistency: The precise control over the heating process ensures uniformity in material curing, leading to higher-quality finished products. This level of consistency is particularly crucial in industries like aerospace and medical, where precision is paramount.

- Energy Efficiency:Microwave molding is inherently energy-efficient, as it directly targets the material being processed, minimizing waste and reducing overall energy consumption. This eco-friendly aspect aligns with the growing emphasis on sustainable manufacturing practices.

- Versatility Across Industries:One of the remarkable features of microwave molding is its adaptability to various materials, making it suitable for a wide range of applications. Our company has successfully implemented this process across diverse industries, attesting to its versatility.

Implementing Microwave Molding in Engineering and Prototyping

As a company specializing in product development, we have seamlessly integrated microwave molding into our suite of services. In the engineering phase, microwave molding offers rapid prototyping capabilities, allowing our clients to iterate and refine designs swiftly. The efficiency of the process ensures that even complex prototypes can be produced with precision, meeting the stringent requirements of industries like aerospace and robotics.

Moreover, the speed and accuracy of microwave molding empower our clients to test and validate their designs in real-world conditions promptly. This approach not only accelerates the product development cycle but also reduces the risk of design flaws, contributing to overall project success.

Low-volume production is an arena where microwave molding truly shines. The process’s ability to deliver high-quality, fully cured components in a short timeframe aligns perfectly with the needs of industries seeking limited production runs. In sectors like medical devices, where regulatory approvals and time-to-market are critical, microwave molding proves invaluable.

Our company has witnessed firsthand the impact of microwave molding in low-volume production scenarios. Whether it’s producing specialized components for medical equipment or crafting intricate parts for automotive prototypes, the efficiency and precision of this process have elevated the standards of our manufacturing capabilities. We grind the material while manufacturing a master model. We incorporate our urethane casting knowledge with the new process to provide products in a short time.

Microwave Molding: A Solution For Different Industries

In the automotive sector, microwave molding has empowered us to produce intricate and lightweight components crucial for enhancing fuel efficiency and overall vehicle performance. From interior panels to exterior trim pieces, the speed of microwave molding has proven instrumental in meeting tight production schedules without compromising quality.

The medical industry demands precision and reliability, and microwave molding has emerged as a key enabler in meeting these stringent requirements. Our ability to produce small-batch, high-precision components has facilitated the development of cutting-edge medical devices, pushing the boundaries of innovation in healthcare.

Aerospace and robotics industries benefit from microwave molding’s capability to produce lightweight yet robust components. The reduced lead times and consistent quality have allowed us to contribute to the advancement of technology in these high-tech sectors.

ARRK’s Team of Expert Engineers

Our reliable team of experts works hand in hand with our clients, understanding their needs and expectations. Our clients can always trust that our engineers will guide each step of the manufacturing process so they make informed decisions regarding their projects.

If you would like to know more of what is the microwave molding process and how it could be implemented in your project, you can reach out to our customer service team who will be happy to assist you.