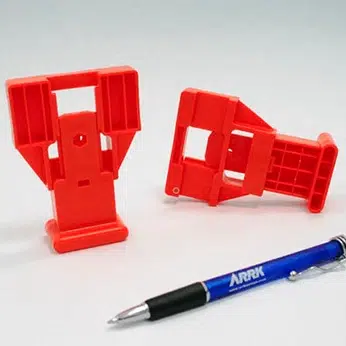

INJECTION MOLDING

PROVIDING QUALITY PARTS FOR YOUR HIGH, MEDIUM, AND LOW VOLUME INJECTION MOLDING NEEDS

MORE CHOICES

Small to large parts

BEST QUALITY AND PRICE

Global resources for quality and reasonable cost

FREE UP YOUR RESOURCES

Reliable production services

ARRK'S INJECTION MOLDING

ARRK'S INJECTION MOLDING SERVICE

EXPANDED PRODUCTION SERVICES AND PART FINISHING OPTIONS

-

SPECIALTY MOLDING

- Thin Walled Parts

- Clear Parts

- High Polished Parts

- Two Shot

- Insert Molding

- Over Molding

- In-Mold Decorating

-

SPECIALTY OPERATIONS

- Silk Screen / Pad Printing

- Laser Etching

- Painting

- Chrome Plating

- Powder Coating

- Ultrasonic Welding

- Heat Staking

QUALITY PARTNER

EXPERIENCE

One-Stop Solution

Concept Design

Rough

Sketch

Define Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

One-Stop Solution

Concept Design

Rough

Sketch

Define

Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre/ Mass Production

DFM

Tooling

Production

BLOGS & NEWS

What Methods Can Produce Rapid Prototype Machined Parts?

Rapid prototype machined parts can be produced using different kinds of manufacturing methods. We are experts in rapid prototyping, learn more about it.

ARRK’s Comprehensive Manufacturing: Soft Goods Prototyping

Our engineers know that soft goods prototyping requires meticulous processes and methods, same as using high-quality materials to achieve excellent results.

A Powerful Fusion: CNC Machining Rapid Prototyping Method

At ARRK, we are constantly looking for ways to enhance our manufacturing processes and product development services, like CNC machining rapid prototyping.

Plastic Molding and Manufacturing for Diverse Industries

Plastic molding and manufacturing have a long trajectory in modern processes for diverse industries. Injection molding is one of ARRK’s preferred solutions.

TESTIMONIALS

INDUSTRIES

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation