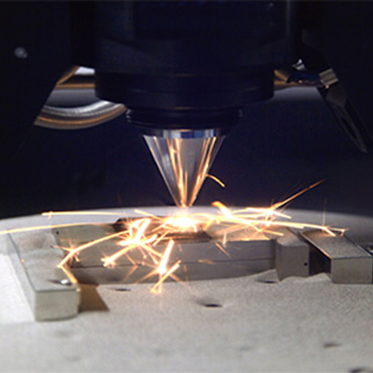

DIRECT METAL LASER SINTERING

Home » Direct Metal Laser Sintering

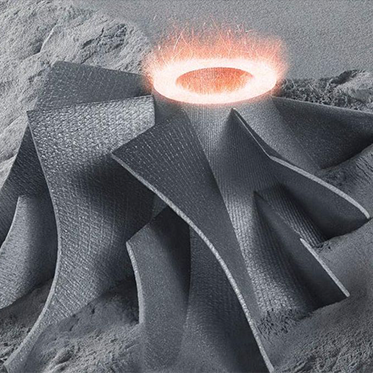

ARRK’S DIRECT METAL LASER SINTERING SERVICE PROVIDES CUSTOMERS WITH THE ABILITY TO PRODUCE COMPLEX METAL PROTOTYPES

FUNCTIONALITY TESTING

DMLS will provide you with a superior strength to withstand rigorous testing

HIGH QUALITY

Provides high quality metal prototypes with outstanding accuracy

FINISHING EXPERTISE

Services including media blasting, polishing, and painting to match final product

DIRECT METAL LASER SINTERING

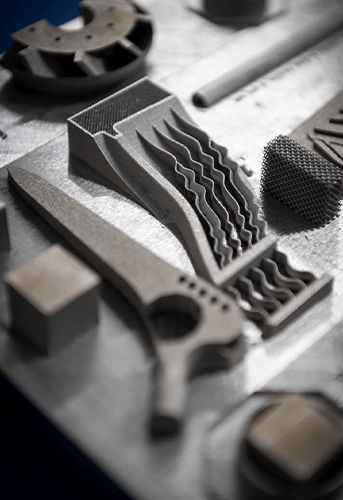

DESIGN ADVANTAGES OF DIRECT METAL LASER SINTERING

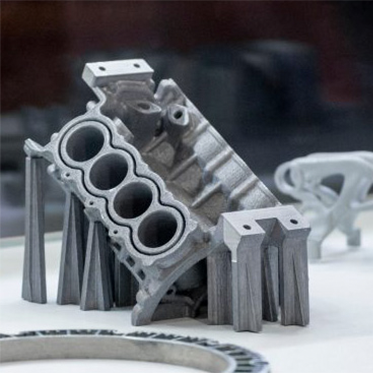

- 3D Printing’s maximum design flexibility allows you to streamline metal component design to include part consolidation. This reduces assembly by welding speeding up prototyping and production reducing time to market.

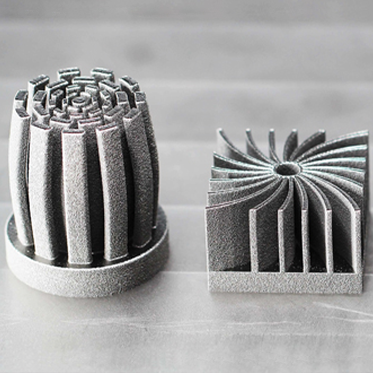

REACHING PART PERFORMANCE GOALS

- DMLS provides the opportunity for design optimization. It can build hollowed geometries and open lattice to replace solid structures within a part with the goal of maximizing performance while minimizing material and weight.

OUR EXPERTISE AND MATERIAL OPTIONS IN YOUR PROTOTYPES

- ARRK offers different material options Stainless steel, Aluminum, Inconel, Titanium, Cobalt Chrome, with our DMLS. We believe in combining the newest, latest, and greatest technologies with master craftsmanship to bring your products to market quickly and economically.

EXPERIENCE

One-Stop Solution

Concept Design

Rough

Sketch

Define Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

One-Stop Solution

Concept Design

Rough

Sketch

Define

Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre/ Mass Production

DFM

Tooling

Production

PRODUCT IMAGES BY INDUSTRY

- All

- Automotive

- Consumer products

- Defense

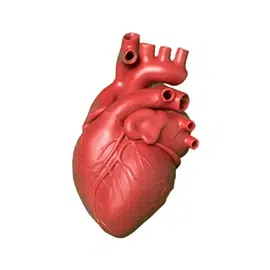

- Medical

- Robotics

BLOGS & NEWS

What Methods Can Produce Rapid Prototype Machined Parts?

Rapid prototype machined parts can be produced using different kinds of manufacturing methods. We are experts in rapid prototyping, learn more about it.

ARRK’s Comprehensive Manufacturing: Soft Goods Prototyping

Our engineers know that soft goods prototyping requires meticulous processes and methods, same as using high-quality materials to achieve excellent results.

A Powerful Fusion: CNC Machining Rapid Prototyping Method

At ARRK, we are constantly looking for ways to enhance our manufacturing processes and product development services, like CNC machining rapid prototyping.

Plastic Molding and Manufacturing for Diverse Industries

Plastic molding and manufacturing have a long trajectory in modern processes for diverse industries. Injection molding is one of ARRK’s preferred solutions.

TESTIMONIALS

INDUSTRIES

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation