Product development is an ever-evolving industry. Since innovation propels ideas from conception to reality, at ARRK, a global leader in product development support services, we understand the paramount importance of prototyping solutions in bringing groundbreaking concepts to life.

To remain relevant in the market, companies should embrace innovation. However, committing to it can represent a big expense with a variable risk of failure. For that reason, prototyping is a game changer in the manufacturing field. Here, we explore the art and science of prototyping, understanding its critical role in engineering, tooling, and low-volume production to drive success in any industry.

What Is Prototyping?

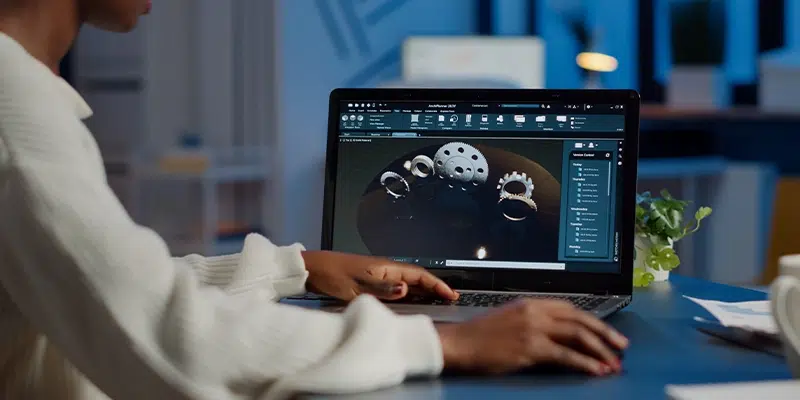

Prototyping stands as a linchpin in the product development process, serving as a tangible manifestation of creative ideas. It is the bridge between concept and execution, allowing designers, engineers, and innovators to refine and validate their ideas before full-scale production. At ARRK, our commitment to excellence is reflected in our advanced prototyping that empowers clients to navigate the complexities of product development with confidence and precision.

The prototyping stage plays a pivotal role in transforming theoretical designs into tangible prototypes that can be tested and refined. Whether it’s validating structural integrity, assessing material compatibility, or refining intricate details, our advanced prototyping techniques provide engineers with the tools to ensure their designs meet and exceed industry standards. With our design model process for prototyping, our team of experts will ensure that the prototype looks and feels like a definite product from the start, employing a wide range of prototype finishing options..

Rapid Iteration for Enhanced Designs

The iterative nature of prototyping is a game-changer in product development. Our Rapid Prototyping services enable engineers to quickly iterate and refine their designs based on real-world testing and user feedback. This agility not only accelerates the development timeline but also significantly reduces the risk of flaws, ultimately leading to more robust and innovative products.

Material Flexibility

ARRK recognizes that material selection is a critical aspect of successful prototyping. We offer a wide range of prototype materials, from plastics and metals to elastomers, allowing engineers to choose the best-suited material for their specific application. This flexibility ensures that prototypes accurately reflect the intended performance and characteristics of the final product.

When it comes to manufacturing, tooling precision is non-negotiable. Prototyping extends its influence into the tooling phase, where molds and dies are crafted to exact specifications. Our advanced prototyping technologies seamlessly integrate with tooling processes, ensuring that the tools produced are not only precise but also optimized for efficiency and durability. Some of our star methods are urethane casting and 3D printing.

The synergy between prototyping and tooling at ARRK is exemplified by our smooth transition from prototype to production tools. Our experts leverage prototyping insights to refine tooling designs, minimizing iterations and streamlining the entire manufacturing process. This integrated approach not only enhances precision but also significantly reduces time-to-market for our clients.

Customizable Solutions for Diverse Industries

For decades ARRK has worked for different industries with an emphasis on medical, consumer electronics, automotive, aerospace, and defense. We understand the diverse needs of our clients, and our team of experts provides customizable prototyping solutions that cater to each client. Our prototyping expertise is tailored to meet the unique challenges and specifications of each industry, ensuring that the end products exceed expectations

Low-Volume Production Excellence

In the competitive landscape of manufacturing, low-volume production holds a unique position, often demanding a delicate balance between cost-effectiveness and quality, offering an efficient and cost-effective means of producing small quantities of high-quality parts. This kind of production can benefit those who are working in the tasting stage, entering the market with a new proposal, same as for those who offer unique products that come in small batches for limited editions.

The integration of prototyping into low-volume production at ARRK is a strategic move to accelerate time-to-market for our clients. The insights gained during the prototyping phase inform and optimize the production process, ensuring that each manufactured part meets the highest standards of quality and performance (without dismissing aesthetics).

Our services contribute to cost efficiency by minimizing the need for extensive tooling and avoiding costly modifications during mass-scale production. This approach allows clients to test the market, validate designs, and respond to evolving demands without committing to large production runs, striking a balance between cost-effectiveness and flexibility.

As industries continue to evolve and embrace the challenges of the future, ARRK remains at the forefront, offering advanced prototyping to redefine the possibilities of innovation. With us, clients not only navigate the complexities of product development but emerge as trailblazers, setting new standards of excellence in their respective fields.

Reach out to our customer service department to learn more about our services and dare to embrace innovation.