ARRK is a global leader in product development support services, we recognize the paramount importance of precision, quality, and versatility. For decades, we have worked with different industries, gaining experience and our clients’ trust.

Cast urethane is suited for innovation since it offers a plethora of benefits to our processes. We are one the best cast urethane manufacturers in the industry nowadays. In this article, we will explore the multifaceted world of cast urethane manufacturing and how it plays a pivotal role in engineering, prototyping, tooling, and low-volume production.

What is Cast Urethane?

Urethane casting, also known as polyurethane casting, is a versatile and cost-effective manufacturing process that involves the use of liquid polyurethane to create prototypes, functional parts, and components. This process is particularly well-suited for Low-volume Production runs, prototyping, and applications where precision, flexibility, and quick turnaround times are crucial.

Cast urethane manufacturing stands as a beacon of innovation, offering a myriad of advantages that elevate it above traditional manufacturing methods. This process provides a cost-effective and rapid solution for creating high-quality prototypes and end-use parts. Rapid Prototyping is one of the biggest advantages of this method.

Engineering Excellence

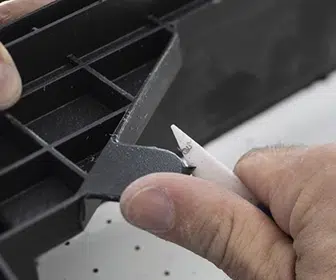

In the realm of product development, precision is non-negotiable. ARRK’s urethane casting services excel in creating components with intricate geometries, tight tolerances, and exceptional surface finishes. The ability to replicate intricate details makes cast urethane an ideal choice for engineering applications where precision is key.

The Importance of the Prototyping Stage

Prototyping is the heartbeat of innovation, and cast urethane manufacturing breathes life into this process. The speed and flexibility offered by cast urethane allow for the rapid iteration of designs, enabling engineers and designers to test and refine their concepts swiftly. This agility significantly reduces time-to-market, a crucial factor in today’s competitive business landscape. For those who are testing their designs and need to be able to make changes rapidly and at a low cost before engaging in mass production, cast urethane is the best choice.

Tooling is the backbone of manufacturing, and cast urethane manufacturers play a pivotal role in creating high-quality molds and tooling solutions. The durability and resilience of urethane molds make them well-suited for low-volume production runs, offering a cost-effective alternative to traditional tooling methods. The versatility of cast urethane tooling ensures that it can be employed across various industries and applications, from automotive components to consumer electronics.

Low-Volume Production Paradigm

While mass production often takes center stage in manufacturing discussions, the importance of low-volume production cannot be overstated. Cast urethane manufacturing provides an ideal solution for companies looking to produce small quantities of high-quality parts without the prohibitive costs associated with traditional manufacturing processes. This capability is particularly beneficial for niche markets, custom applications, and initial product launches.

Ensuring the highest quality is a cornerstone of our company. At ARRK, we adhere to stringent quality control measures, employing advanced technologies and processes to guarantee the consistency and reliability of the produced parts. From material selection to post-processing techniques, every step is meticulously executed to meet and exceed industry standards.

Our commitment to high-end quality products matches our commitment to employing environmentally friendly options when it comes to our manufacturing processes. Cast Urethane generates minimal waste, and the materials used are often recyclable. Additionally, the energy efficiency inherent in cast urethane manufacturing aligns with the global push towards greener and more sustainable manufacturing practices. By utilizing such methods, we reduce our carbon footprint.

As a global company providing product development support services, we understand the importance of seamless collaboration and a worldwide perspective. Through our expertise with cast urethane, we contribute to the global product development landscape by providing a reliable and efficient solution that transcends geographical boundaries. This facilitates international partnerships and accelerates the exchange of ideas and technologies across the globe.

In Summary: Applications of Urethane Casting

- Prototyping: Urethane casting is widely used in product development for creating prototypes. It allows designers and engineers to quickly iterate and test designs before committing to mass production.

- Low-Volume Production: For industries where producing a small number of parts is more economically viable, such as aerospace, automotive, and medical devices, urethane casting offers a cost-effective solution.

- Functional Components: Urethane casting is suitable for producing functional components, including gaskets, seals, gears, and other parts with specific material properties.

- Customized Products: The process is well-suited for creating custom or specialty products, where unique design requirements are essential.

Embracing the excellence of cast urethane allows companies to navigate the intricate terrain of modern product development with confidence and efficiency, ultimately turning innovative concepts into reality. Working side by side with our team of experts will lead your product to the next level. Get in contact with our customer service staff to learn more about our processes.