ARRK & CNH Industrial’s collaboration is nothing short of a triumph in precision printing and aesthetic finishing.

The agricultural machinery industry is chockfull of movers, shakers, and innovation. With technological advances in the industry’s machinery sector moving at unimaginable strides, it is vital for companies focused on agricultural advancements to plant radical seeds to cultivate a better tomorrow.

A laser clear focus on the future, top-notch materials and expert craftsmanship are key to any project’s market success.

However, how will these ideas be presented to the agricultural market to drum up excitement and result in victory over the competitors?

Within this case study, we’ll focus on the collaboration between ARRK North America and CNH Industrial, a leading industry player in the development of agricultural and construction equipment and machinery, in creating scaled-down models of 3 of the company’s agricultural tractors utilizing ARRK’s advanced 3D printing technologies and in-house finishing techniques.

Customer Request

ARRK's solution

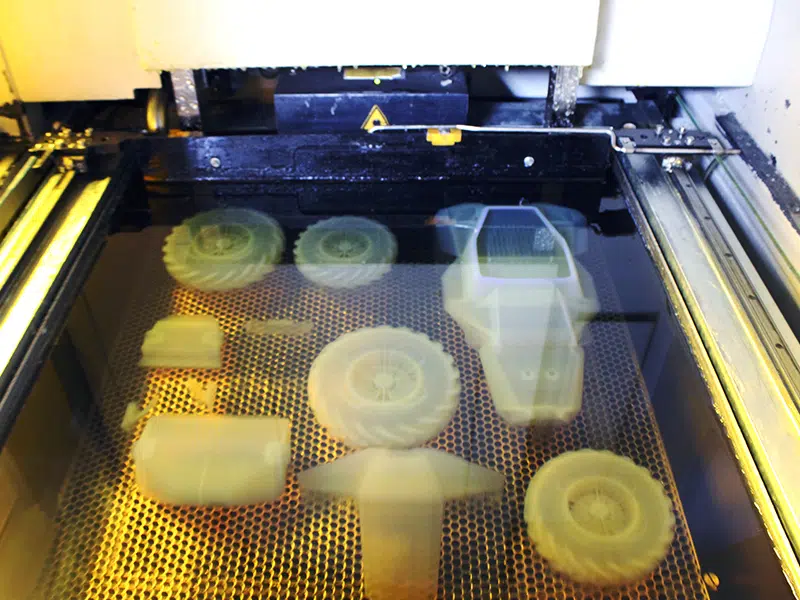

In addition to this, Flex was chosen as the optimal material to carry out this task. Flex is a transparent, amber-colored resin that produces polypropylene-like parts with very high durability. Once the SLA printing process had concluded, ARRK’s finishing department took over the mission of completing the scaled-down models.

While the request was initially for the scaled-down models to be crafted and presented in their raw stage, with no finishing, the ARRK North America team suggested the addition of finishing skills to these pieces would be the crown jewel on an already spectacular project.

During this phase, our craftsman teams were responsible for providing a splash of color to each piece. After a series of tests and with a final color sign-off, our teams were free to move on to completing the finishing process. An initial base coat was applied to prepare each part, and this was followed by our expert airbrushing techniques, finishing off with a coat of clear sealer to protect the paint and provide a finish that is sure to last.

Finally, the time has come for these models to be reassembled, resulting in a remarkable scaled-down models of CNH Industrial’s tractors and farm machinery.

Project outcome

“The key to successful projects lies in organization and effective communication. These elements were fundamental to overcome the challenges and achieve a harmonious collaboration throughout the process.”

Marcela Inzunza – ARRK Project Manager

This case study highlights ARRK Noth America’s ability to address specific customer challenges using advanced manufacturing technologies. The successful collaboration between the two companies underscores ARRK’s commitment to excellence and customer satisfaction. This project lays the groundwork for future collaboration opportunities, cementing ARRK as a trusted partner in the implementation of advanced 3D printing solutions in the agricultural and construction machinery industry.