Case Study - BMX Bicycle Frame

For this project, we’re jumping across the pond to Spain, directly into the ARRK Barcelona plant to catch up with Santi. For the past 20 years, Santi has been the technical commercial representative for the region, forging strong relationships with exceptional customers such as studio 4id. For nearly two decades, studio 4id has specialized in vehicle design and new mobility products in the Barcelona Market.

Customer Request

« Technical meeting between the client and ARRK, at The 4id studio

ARRK's solution

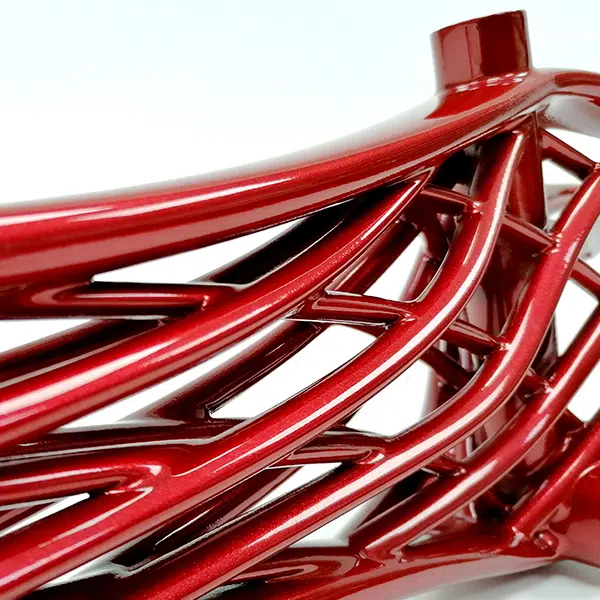

As Santi explains, the bicycle frame geometry, including its internal geometries with difficult access, almost immediately discarded the use of our CNC service. However, 3D SLA technology, or Stereolithography, proved to be the best option to obtain optimal results. “It’s critical for the ARRK team to bring this project to life to perfectly showcase our SLA technology possibilities at achieving spectacular geometries in under 24 hours” is perfectly expressed by Santi.

Project outcome

HIGH-QUALITY RESULTS DIRECTLY FROM ARRK’S WORKSHOP

As Santi cleverly sums up: “As prototype manufacturers, we interact closely with designers from all over the world on a daily basis, and we appreciate their talent! Backed up by a 15-year collaboration with studio 4id, we crafted unique samples to perfectly showcase the 75 materials and finishing samples available through ARRK. This includes clear or colored resin, sand blasted, lacquer, satin, matte, gloss or metallic finishes; the possibilities are endless! This is a key support tool that ARRK can showcase to customers.”