The manufacturing industry is increasingly becoming more competitive and capable each day.

The wide variety of available products and the many needs they cover have raised the bar and demanded developers to go further and deliver new technologies to meet today’s expectations.

At ARRK North America, we have over 70 years of experience in the field. Dedicated to refining several advanced manufacturing processes, we have achieved results with the highest quality and detail. Vacuum Casting is one of our favorite processes because it always provides an excellent outcome, so we dare to say it is superior in many ways. But what makes Vacuum Casting silicone mold so special?

Vacuum Casting: Quality You Can Touch

We have talked about why Vacuum Casting prototyping projects are so successful, and part of the answer is because of the attributes silicone brings. The properties of this material are exceptional: it shows high elasticity, high compressibility, low toxicity, and thermal & creasing resistance, among others. Because of the former, it’s fair to say no other method can achieve the same results, which are the following:

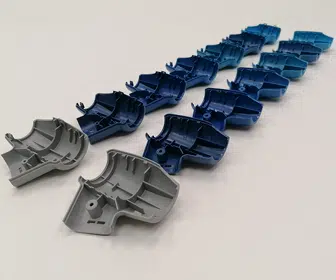

- Variety of highly detailed finishes: The elastomers and resins are poured inside the silicone mold and allowed to cure. Beforehand, however, the selected colors are included in that mix, as well as the consistency that will result from the curing process. With the texture provided by the interior of the mold, the component will have a highly detailed finish; exactly the one requested by the customer.

- Perfect fit for low demand: Since each mold can be used around 20 to 15 times without diminishing quality, Vacuum Casting is ideal for low demand, whether clients need a few prototypes or require a physical model to make design changes. In any case, it works very well for small companies, but also for large corporations that require small batches.

- Flawless method to achieve complexity: Silicone has a high tear strength that results convenient when demolding. It allows for intricate designs and complex shapes, and there is no need to waste molds by cutting them, as it happens with Injection Molding, since each mold maintains its exact shape for 10 to 15 batches straight, lowering costs and achieving quality every time.

There are many benefits Vacuum Casting provides to the manufacturing and prototyping industry, and we, at ARRK North America, take advantage of them when developing components for our customers. This process has been a perfect fit for industries such as Medical, Automotive, Consumer Electronics, Aerospace, and Robotics.

In addition, we also provide custom 3D Printing solutions, which is the best way to create a precise master model, allowing the silicone to reach its full potential. Whether you’re looking for Stereolithography, Selective Laser Sintering, Polyjet 3D Printing, FDM 3D Printing, or Direct Metal Laser Sintering.

If you’d like to get your project started, don’t hesitate to contact us. Visit our website and get a quote! You’ll be amazed by the results your company can achieve with Vacuum Casting silicone mold.