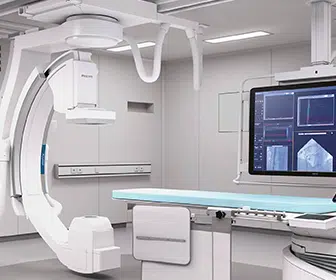

Medical Aesthetic Devices have marked a watershed in cosmetic medicine. Nowadays there is a wide range of treatments and procedures applied for cosmetic purposes, making them more accessible and efficient. Clinics and specialists tend to rely on technology to access a wider variety of solutions they can offer their patients to achieve the desired results.

Today, laser technology can be found in the form of tattoo, hair, and scar removal devices, as well as body sculpting machines. These result from the union between high tech and science, which come to life after extensive research and testing. The final result, however, is only possible due to the Product Design and Development process.

Here at ARRK North America, we specialize in providing the most advanced manufacturing solutions, guiding our customers to find the option that better suits their production needs while attaining the best quality of materials and procedures.

Medical Aesthetic Devices are no easy task. Different components make up the whole product and several steps must be completed before having the finished device in your hands. Some of these steps are Rapid Prototyping and 3D Printing, processes that have reached incredible advances, providing very detailed prototypes even when it comes to complicated designs.

Custom Manufacturing

3D Printing is a tool that offers flexibility and speed. We can use various types of resins to make custom 3D Printing models and deliver them within weeks. With the help of Stereolithography, a wide range of models are created, varying from size and shape to texture and color.

Rapid Prototyping is a great choice for customers who want to test their design before carrying out the final production. It’s possible to bring your design to life from the start, making a reliable prototype that will offer a glance at what a bigger production would look like. This quick process helps companies during the testing process, making sure the prototype meets all requirements and is fit for its purpose.

Once we have the 3D prototype or master model, we can move to the next stage, for which we advise you to try Vacuum Casting.

Vacuum Casting for Medical Aesthetic Devices

There are different kinds of prototyping processes, which are carefully chosen according to the client’s needs, such as type of product, volume of production, and budget, to mention a few.

The advantage of Vacuum Casting (also known as Urethane Casting or silicone molding) is that it provides a more flexible and faster alternative compared to Tooling and Injection Molding.

Vacuum Casting is an excellent option for designs that are still in the prototyping stage since modifications can be made at an attainable price and short time. One Vacuum Casting silicone mold can produce from ten to twenty pieces depending on the complexity of the design, which makes it ideal for Low-Volume Production.

In the Aesthetic Medicine field, the tendency is to focus on quality over quantity. Vacuum Casting is a good option for these types of devices since it works wonderfully for Low-volume Production.

Technology is rapidly changing and advancing. That is a fact to take into consideration when manufacturing Medical Devices. By keeping a small production, companies can ensure getting their products into the market before new technology makes them outdated and improvements to the initial design would have to be made in order to remain competitive.

When it comes to machines, design, and finishing matter, especially in the Medical Aesthetic industry where tidiness is associated with hygiene and trustworthiness, it is necessary to match the visuals of the device with its purpose and efficiency.

At ARRK North America, we not only manufacture high-quality products that will operate perfectly, but we care about delivering either parts or complete machines that look top-notch. Our team has years of experience and will suggest materials and processes that match and align with the design our clients have in mind. We offer a wide range of finishing options for both the prototype and the final product.

If our clients need to speed up their production, we can help them attain it by manufacturing parts of the device or the whole product. Each project will vary its period of completion according to the volume, process, and goals.

We will work with your company’s needs so you receive products that are altogether what they expected. Reach out to us to get a free quote and more information about the services we provide. We will help you throughout the process of bringing your project to life! Contact us to get a quote or for more information.