Every day, in order to achieve goals and meet the needs of a demanding market, manufacturing companies face various challenges, both in strategy and supply chain. For this, a company’s structure has multiple levels of management, sales, production, and logistics.

However, even when a successful company has the best tools, skilled employees, and the proper organizational chart, some processes cannot be carried out in-house. This is due to the large investment required and the fact that profits may not be able to cover it.

In these cases, there are teams dedicated to supporting companies with specific processes. At ARRK North America, we are experts in Product Design and Development services and carry out Low-volume Manufacturing Processes that allow us to provide quality, cost-efficiency, and excellent results. Let us tell you more about it.

Low-volume Strategies for Small and Large Companies

Our over 70 years of experience have given us the knowledge and technical know-how to master Low-volume Production, an advantageous approach that improves performance and is key to the success of small to large companies requiring specific processes and results in their Product Development supply chain.

High-mix Low-volume (HMLV) Manufacturing provides the opportunity to get a wide range of components and products in small quantities through specific processes selected according to the company’s needs. That is, depending on specifications and goals, companies choose the best method and materials to achieve outstanding results and performance.

How does low volume benefit my production? At ARRK, we have specialized in the following processes to get companies the quality they deserve:

- Urethane Casting

Also known as Vacuum Casting, Urethane Casting focus on developing parts or whole products with a master model based on a 3D design. This master model allows the reproduction of silicone molds, in which the liquid resin is poured and allowed to cure. After a few days, the components are ready, and the demolding process begins. Urethane Casting is a highly versatile process that enables the creation of flexible or rigid, opaque to glossy, products. Manufacturers can create the most complex designs and make them a reality with the flexibility of silicone molds.

Materials:

Components made with high-quality resins, mixed to obtain desired results, such as color, finish, and properties. Polyurethanes and thermoplastics such as ABS, urethane rubber, clear, etc.

Additional finishing options:

Spray painting texture/gloss, logo and graphics application, electro-forming plate, spin line, sputtering, vacuum metalizing.

Cost-effectiveness

This is one of the best options for any company looking to increase savings, as the cost of silicone molds is not high, and it does not require a large investment. In addition, each mold can make from 10 to 15 parts without losing quality.

- Injection Molding

As one of the most successful processes worldwide, Low-volume Injection Molding is a manufacturing process that works by melting thermoplastics and injecting them into a metal mold that will give shape to the product.

Widely used and convenient, as the process is carried out by a machine, Injection Molding provides companies with high-quality products and cost-efficient solutions for their product development needs.

Pros:

Injection Molding works perfectly for Low-volume Production, but also adapts to medium and large-volume batches. It also provides a low cost per part, low waste, and repeatability.

Specialty operations:

Silkscreen, laser etching, painting, chrome plating, powder coating, ultrasonic welding, and heat staking.

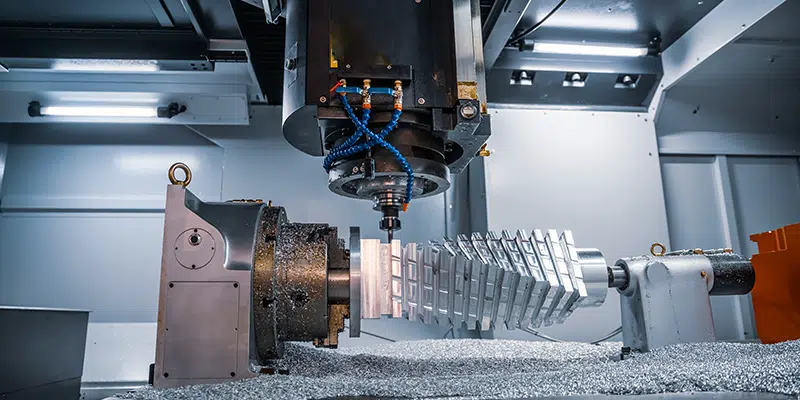

- CNC Machining

CNC Rapid Prototyping, also known as Computer Numerical Control Machining, is an automated manufacturing process involving programming and mechanical design to function.

Based on digital instructions, also known as the G-code, CNC machines subtract material from a piece of steel, titanium, or aluminum and create parts and prototypes exactly as the 3D model provided by the designers.

Pros:

This process provides high precision since the machine follows specific programming instructions and creates a detailed finished piece.

Processes:

We carry out 3-axis and 5-axis CNC mills for accuracy and adapt the rotation of tools in order to create the desired shapes.

Materials:

Steel, titanium, aluminum. The wide range of available materials compatible with CNC machining makes the production of a final part even faster than traditional manufacturing.

Several specifications regarding Low-volume Manufacturing Processes can only be discussed when knowing the details of each project. Fortunately, at ARRK North America, we advise our customers throughout the whole process to achieve goals, get outstanding quality, and meet all the requirements for a successful result.

We are Low-volume Production experts focused on delivering precision, cost-efficiency, and the highest quality worldwide. If you require this convenient process to improve your company’s productivity, we are the right choice! Contact us to learn more about our comprehensive solutions.