The process of manufacturing products with complex geometry is possible nowadays, thanks to the expert use of manufacturing processes. There are a lot of different processes that can be utilized to create a challenging type of product. ARRK North America Inc. would like to show the different ways we can help you get your design transformed into a real product.

ARRK Capabilities:

- LOW VOLUME PRODUCTION

ARRK doesn’t shy away from Low Volume Production. Low-volume manufacturing usually involves the production of 50–100,000 parts, acting as a bridge between one-offs and full volume production, making it one of the reasons many companies reject the projects, but not us. We understand the importance of including Low Volume capabilities to test your product, or to substantiate the needs of your company’s project.

- RAPID PROTOTYPING

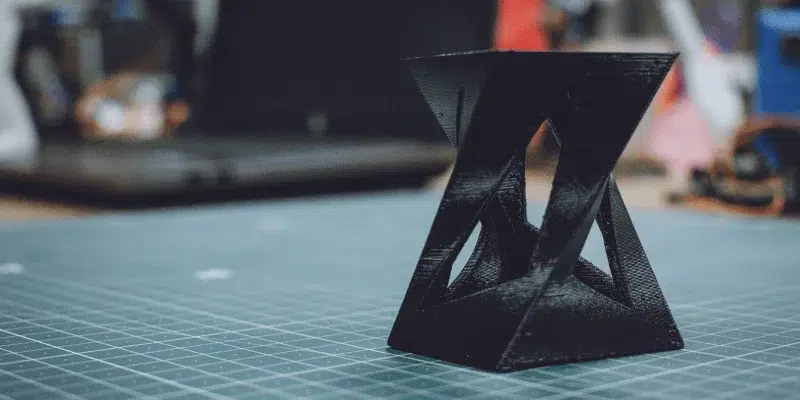

Rapid prototyping is a type of manufacturing that uses 3D CAD software to create a physical object from digital designs. The creation of the component, model, or assembly usually takes place using additive manufacturing, which is more commonly known as 3d printing.

- TOOLING

Tooling, or machine tooling, is the backbone of every manufacturing and molding process. Tooling refers to building the different types of components and machinery needed for production, like molds, jigs, and fixtures.

- ENGINEERING

Our customers are taking advantage of a one-stop product development process that we implement in our End to End services. ARRK brings together highly qualified specialists to provide customers with top technical know-how, and our craftmanship uses the necessary technologies to deliver outstanding service in terms of quality, precision, and promptness.

Types of manufacturing processes:

CNC Machining

CNC machining is a great way to produce high-quality parts quickly, efficiently, and at a reasonable price.

Urethane Casting

There are many ways to cast urethanes, but most people choose to use a vacuum-forming machine. This method uses a heated mold which creates a negative impression of the object being formed, melted plastic is then poured into the mold and allowed to harden, once it has hardened, it is removed from the mold and finished.

Injection Molding

Some injection molding machines available are manual, semi-automatic, and others are fully automatic, but all of the work on the same principle of injecting plastic materials molten by heat into a mold and then cooling and solidifying them.

3D Printing

3D printing has become a popular way to produce custom objects. It allows people to print out almost anything they want. This includes everything from toys to jewelry, but it can also be used to make medical devices, prosthetics, auto parts, and robotics.

Which type of product do you need to build with complex geometries?

At ARRK North America Inc., we want to help as many companies as possible to achieve their goals, that’s why, with the guidance of our team of experts in the field, our many locations all over the world, and the vast number of services we offer, we know ARRK is the best option for product development for companies of all sizes.