ARRK EUROPE SUPPORTING STUDENTS OF THE UNIVERSITY OF ELISAVA REACH SCHOOL OF DESIGN PROJECT GOALS.

For many years now, ARRK Europe has supported engineering students from Elisava, the prestigious school of design and engineering in Barcelona. In 2021 ARRK was proud to support the Elisava Racing Team, a group of students whose project was to design a prototype electric motorcycle for mountain rescue operations.

Customer Request

Over the course of relationship with the university, ARRK Europe has helped educate and share its knowledge of “Rapid Prototyping Technologies” with many students on processes like stereolithography (SLA), powder sintering (SLS) and CNC machining technologies. Demonstration parts have also helped students to understand the degree of precision of these technologies, the rendering of the materials, paints, and the quality of the finishes that can be obtained in 3D printing.

As Santi Pladellorens, ARRK’s senior representative with Elisava University states “3D printing & prototyping has become essential in product development. All engineering students must now know the possibilities and constraints of 3D printing technologies available on the market to carry out their projects.”

In 2021 students of Elisava University approached ARRK for help with their Dayna Evo project, in order to create a 100% electric motocross motorcycle for mountain rescue. In addition to the support given to the design of the motorcycle, the students also dealt with the issue of the weight of parts to minimize the vehicle’s energy consumption.

ARRK's solution

Given its experience and mastery of complex projects in terms of vehicle optics, ARRK offered to supply the deflector, side lights, front and rear lights, turn signals and brake lights for the Dayna Evo motorcycle. To meet the technical specificities of each part, ARRK combined different 3D printing and prototyping technologies, such as stereolithography (SLA), selective powder sintering (SLS) and vacuum casting and delivered aesthetic pleasing and functional prototypes.

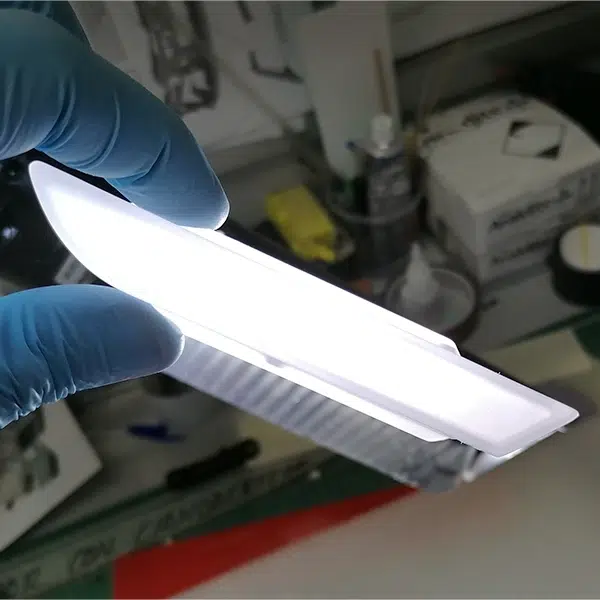

The side lights of the motorcycle are remarkable from a design and technical point of view. They emit a blue light, essential for emergency vehicles. These prototypes are made using SLA technology, in transparent resin. The latter has been painted white to allow the diffusion of light, to give the illusion of a transparent piece edged in white and to conceal the blue LEDs fixed inside the optics. The black reflector is produced using SLS technology.

Arrk, prototype expert in vehicle optics »

The Dayna motorcycle deflector was produced in smoked transparent resin. For the front headlight, being a safety part, we had to obtain a perfectly transparent and shiny part. After machining a master with very precise details, we vacuum cast the prototype in polyurethane resin to obtain a very solid part. As for the reflector, it was made using sintered powder with a chrome finish applied to reflect the light.

The rear lighting system, consisting of the rear light and the 2 indicators, was also made from a silicone mold using a machined PMMA plastic master.

We were thus able to cast complex geometry parts in transparent and smoked resin, which would give the bike a very modern look.

We were thus able to cast complex geometry parts in transparent and smoked resin, which would give the bike a very modern look.

Simpler in shape, the front indicators have been printed in SLA clear resin, with a clear lacquer applied as a finish. Transparency being an important feature but less so when compared to the front headlight, made it possible to limit the cost of production of the parts.

Project outcome

ARRK were delighted to provide technical assistance to the students at every stage of their project. We gave them advice on:

- Improve the design of parts (angles, thickness) to optimize their feasibility,

- Design 3D files fully usable by a prototype

- Choose the relevant technologies according to the complexity of the parts, the expected material rendering, and the desire to produce the lightest possible components that are resistant to driving on rough terrain

- Assemble the parts of the motorcycle,

- Consider mass production.

« Guiding student engineers throughout the prototyping project

“The collaboration with Elisava University was amazing: its students were both very creative and technically competent. In addition, they were professional and receptive to our recommendations. I believe that this experience was as exciting for them as it was for us!”, concluded Santi.

Our customers are our number one priority. By carefully listening to their needs and providing exceptionally proficient results, we are here to make your ideas happen. ARRK North America, Inc. continuously provides an innovative variety of services readily available to make your projects come true. Our team of experts is standing by to provide consultation and aid in beginning your project. Contact us by phone at (800) 735-2775 or visit us at us.arrk.com and click the Get a Quote feature to be contacted directly by our Business Development team.