Innovation in Panasonic Corporation’s 100th Anniversary Commuter EV Challenges the ARRK Japan Team

Customer Request

The Panasonic Corporation requested an EV Commuter able to transport passengers back and forth without the need for a conductor. The most important factor to be met was that this vehicle would need to be produced with the utmost levels of safety and durability. Further, in order to meet the requirements of the motor, supplied by the Panasonic Corporation, the power unit was designed with a target weight not exceeding 1,600 kg with no passengers.

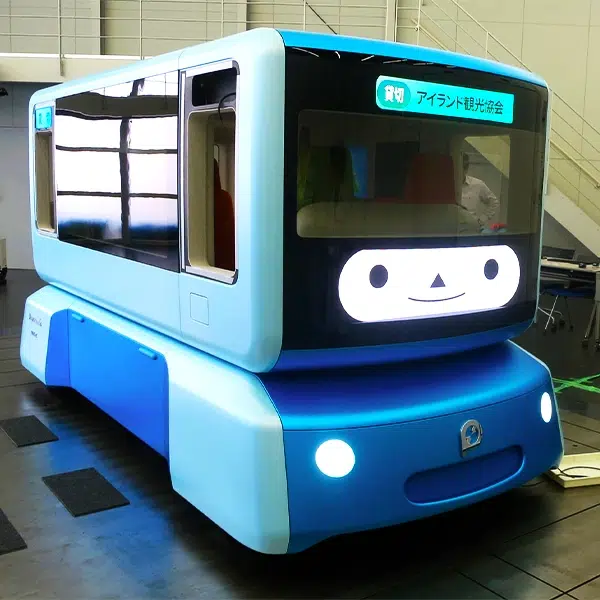

« Panasonic Corporation Model

ARRK's solution

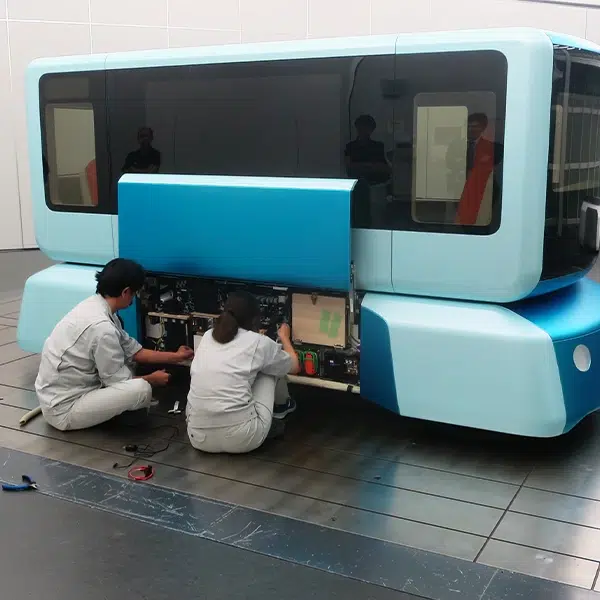

For the cabin, door panels, and exterior panels, the team adopted a molding method called Dry Carbon, a method often used for racing vehicles. Masterfully utilizing this method, the team was able to manufacture the front and rear parts of the cabin in a monocoque structure, successfully keeping the weight to just under 1,400 kg.

ARRK Japan Team Woking »

Project outcome

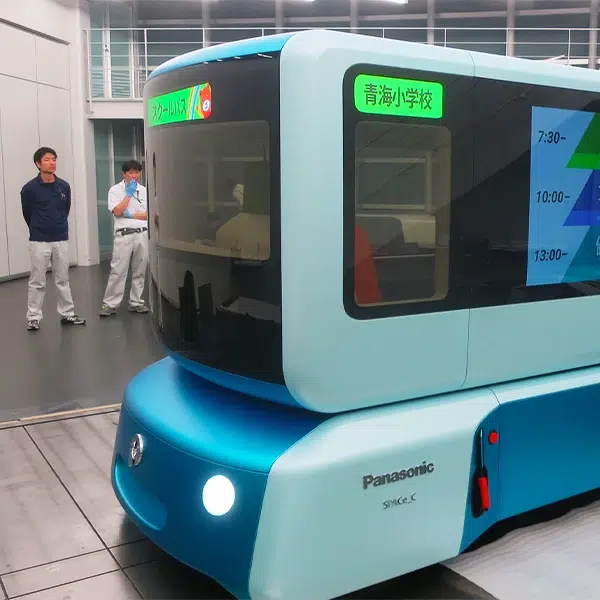

« EV Panasonic’s Corporation Model