The working time with traditional prototyping or rapid prototyping

Working with all the advantages of rapid prototyping for you will allow the project to have the upper hand in optimizing timelines for the specifications of the design into full production. Unlike urethane casting, building another prototype to correct the results is quicker than doing another mold if anything needs to be changed.

Traditional prototypes are made of wood, clay, and foam, among other materials, handled with skill and precise tool handling. All this takes time, an extended amount of time. It was not just for getting a team with such expertise needed, but for the materials to get the prototype just as intended or desired. A lot of testing out could consume most of the time determined for a project.

HOW DOES TRADITIONAL PROTOTYPING DIFFER FROM RAPID PROTOTYPING?

Traditional prototyping takes a good set of skills to handle all the materials and handling them the higher the difficulty of the product to create, the more experience needed. Time is the most consumed in this process.

Rapid prototyping employs software and 3D technology to create a 3D scale model of a physical part or object. The complementary technique used is 3D printing, or additive manufacturing, which allows it not to require any tooling, giving more freedom in testing and shorter prototyping time.

The advantages of rapid prototyping

Engineer, design, and development teams use the following advantages of rapid prototyping to their convenience:

- Faster prototyping phase

- Quicker design iterations

- Close to physical end product standards

- Testing materials out

- Reduction of product development time

- Reduction of development cost

- Reduction of material waste

WHAT DOES IT MEAN FOR YOUR COMPANY?

All these means to your company that:

- Taking the product into the company departments for evaluations needed and making sure everything works as expected before presenting the final product.

- Besides reducing cost by identifying design and reducing design flaws in advance, it would be providing a concept model or a functional prototype.

Concept models provide designers with the opportunity to validate both their ideas and the assumptions that lie behind them.

Functional prototypes enable designers and developers to grasp the details that provide an accurate representation of the finished product by allowing them to verify its validity before it moves onto the next stage.

WHY WOULD IT BE AN ADVANTAGE TO WORK WITH ARRK’S RAPID PROTOTYPING?

Our professional team is experienced in providing custom injection molding solutions to meet the demand for rapid plastic and metal parts manufacturing.

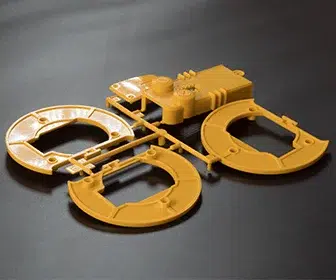

ARRK can combines prototyping techniques with traditional, time-service craftsmanship to produce quality parts quickly and economically. Our injection molding service is ideal for components such as phones, radio covers, hand-held devices, packaging lids, and enclosures.

ARRK also offers its customers a wide range of secondary service options, including machining, powder coating, silk screening, painting, and ultrasonic welding. ARRK uses the latest machines and certified materials to provide customers with outstanding quality, precision, and speed of service.